The will and ability to recycle and reuse wastewater in process plants depends on both economic and societal drivers. Some industries, such as the Food and Beverage industry, have additional regulations with which they must comply such as food safety rules, which creates additional challenges.

While there is technology available that can ensure that absolutely all water can be reused, it is generally the issue of cost that prohibits more water from being recycled. The issue then seems not to be whether the water can be recycled and reused, but how much of the water can be recovered for recycling and the quality of the water.

While most newer plants were constructed with or have been able to add the more modern technology that allows them to achieve state-of-the-art recycling, older plants require many changes before they can even hope to achieve the same levels of recycling.

Depending on the current design and set-up, these legacy treatment facilities could require changes ranging from simply changing the type of RO membranes or resins or adding pre – or post-treatment solutions, which are relatively cheap options, to the more expensive need to make changes to the design.

Solutions such as DOW FILMTEC FORTILIFE antifouling RO products for wastewater recycling and ultra-high pressure RO membrane for increased water recovery are sometimes sufficient to treat feed-water that presents challenges. Once these considerations have been made, a cost-benefit analysis of the system should be undertaken in order to ascertain the issue of regulatory requirements and the system required versus the total cost of water.

In other words, all wastewater streams are potential candidates for recycle/reuse, but it takes a bit of pre-work such as an analysis of the water stream, flow rates, permit limits, constituents, how backwash and reject streams can be treated, and the actual location layout and a variety of other milestones.

Treatment technologies for water reuse include membrane bioreactors, micro-filtration, ultrafiltration, nanofiltration, aerobic treatments, ozonation, ultraviolet treatment and reverse osmosis. Whichever process is used, plants must ensure that they comply with strict purification standards and guarantee process water free from bacteria and viruses.

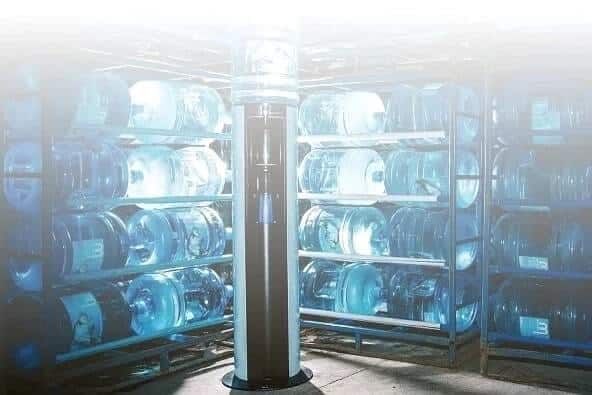

Purchase water coolers and plumbed water cooler from Living-Water.